The reactor

Precise process control for the chemical and pharmaceutical industries

Our stainless steel reactors offer optimal conditions for chemical and pharmaceutical processes. With precise temperature control, flexible agitators, and GMP-compliant design – for reproducible and safe reaction processes.

Product features

Optimized for complex chemical and pharmaceutical processes with the highest quality requirements.

Precise temperature control

Precise temperature control through heating/cooling jackets and integrated measuring and control technology.

Pressure resistant

Certified pressure vessels according to AD 2000 / PED for operating pressures up to 25 bar.

GMP-konform

Pharmaceutical-compliant design according to GMP guidelines for validatable production processes.

Flexible Rührwerke

Various types of agitators (anchor, propeller, disc agitator) for optimal mixing.

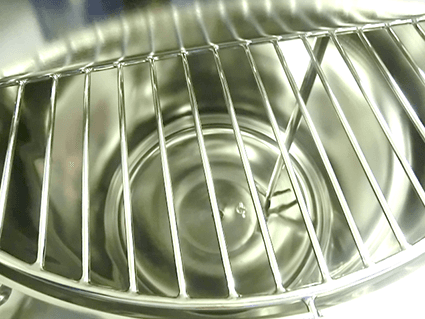

Example: Pharmaceutical process reactor

Stirred reactor for chemical synthesis in pharmaceutical production

Designation

Pharmaceutical process reactor according to PED 2014/68/EU Cat. 3/Module B+D, ATEX RL 2014/34/EU and MRL 2006/42/EU, GMP compliant.

Our reactors are manufactured according to your individual process requirements. The following example shows a typical configuration for pharmaceutical syntheses.

Equipment

| Application Area | Industry: Pharmacy, Chemistry, Biotechnology Products: API-Synthese, Fermentation, Polymerisation |

| Sizes | 10 l – 10,000 l |

| Operating Data | Product Space: p = -1 / +10 bar, t = -20 / +180 °C Double Jacket: p = -1 / +6 bar, t = -20 / +200 °C |

| Material | Product-contacting parts 1.4404/1.4539, Delta Ferrite <1%, with APZ 3.1 AD 2000, Ra <0.8µm, electropolished |

IoT capability with IRIS

Our innovative IoT solution IRIS makes your reactors highly efficient through remote monitoring and control. This also works with your existing vessels.

Other container solutions

Discover more container solutions from our portfolio

Frequently Asked Questions

Answers to frequently asked questions about our reactors

Do you need a reactor?

Let's discuss your requirements. We'd be happy to advise you and create a customized offer.

We usually respond within 24 hours.