Filtrate container

Containers for filtration and chromatography processes

We develop and manufacture containers to your specifications for supporting filtration or chromatography processes, including batch, buffer, slurry, and filtrate tanks. Adhering to current hygiene standards, our systems are primarily used in the pharmaceutical and food industries.

Product features

Specifically developed for filtration and chromatography processes with the highest hygiene standards.

Filtration & Chromatography

Specifically designed for filtration and chromatography processes.

Versatile

Configurable as a mixing, buffer, slurry or filtrate container.

ATEX certified

For use in potentially explosive atmospheres according to ATEX Directive 2014/34/EU.

Hygienestandards

Highest hygiene standards for the pharmaceutical and food industries.

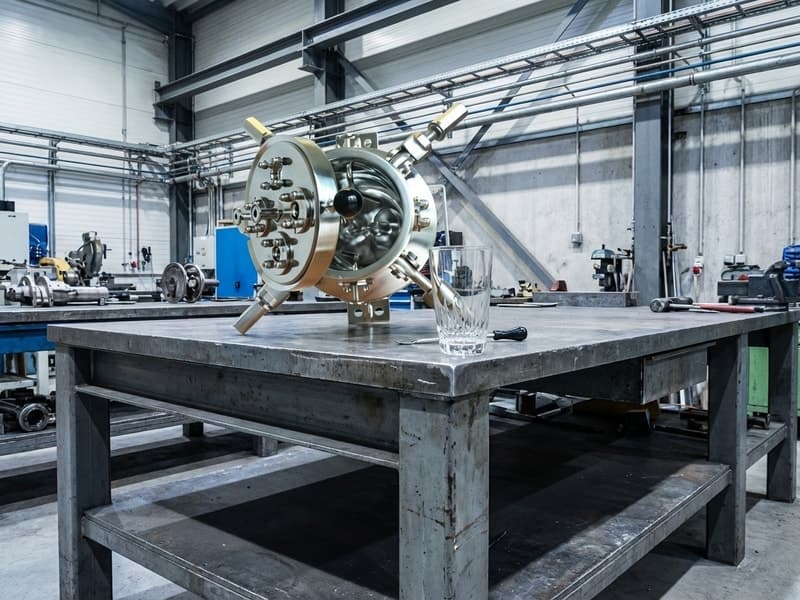

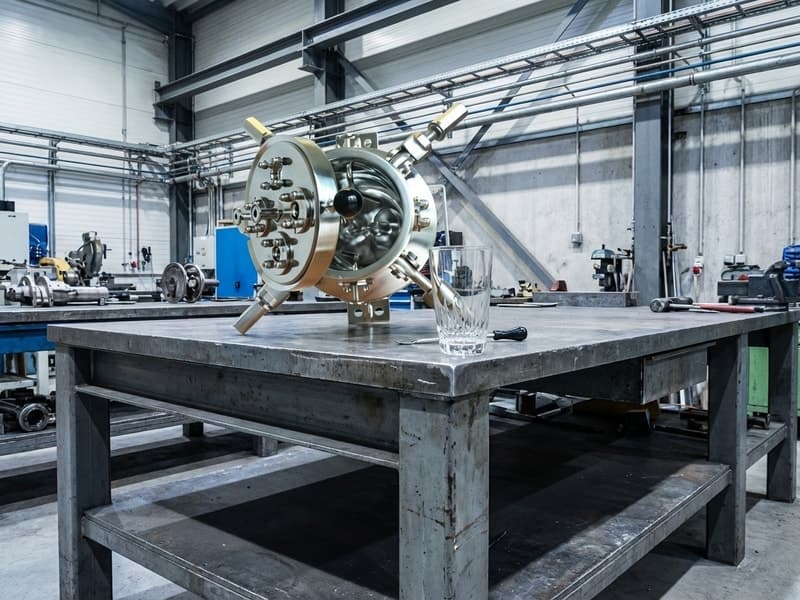

Example: Extraction plant

Pharmaceutical extraction plant for the production of plant extracts

Designation

Pharmaceutical extraction plant for the production of plant extracts. Conformity according to PED 2014/68/EU Cat. 4/Module G, ATEX Directive 2014/34/EU and MRL 2006/42/EU.

Our filtrate tanks are manufactured according to your individual requirements. The following example shows a typical extraction system for pharmaceutical production.

Equipment

| Application Area | Industry: Pharmacy Products: Extraction, lipids |

| Sizes | 500 l – 2,500 l |

| Operating Data | Product Space: p = -1 / +4 bar, t = -10 / +50 °C |

| Material | Product-contacting parts 1.4404/1.4435, with APZ 3.2/3.1 AD 2000, Ra <0.8µm |

IoT capability with IRIS

With our innovative IoT solution IRIS, your filtrate tank becomes highly efficient through remote monitoring and control. This also works with your existing tanks.

Other container solutions

Discover more container solutions from our portfolio

Do you need a filtrate container?

Let's discuss your requirements. We'd be happy to advise you and create a customized offer.

We usually respond within 24 hours.