Coating container

Optimized for coating and spray fluid applications

Our coating containers are optimized for mixing, blending, and stirring processes using aqueous and solvent-based solutions, achieving the smallest possible residual stirring volume. Dispersion and homogenization are paramount for the reproducibility of coating and spray liquid formulations.

Product features

Specifically developed for reproducible coating and spray liquid applications with minimal residual stirring volume.

Low residual stirring volume

Minimum residual stirring volume of approximately 1.0 l for maximum product yield.

Dispersing & Homogenizing

Optimized for reproducible coating and spray fluid applications.

ATEX certified

For safe use with solvent-based media according to ATEX Directive 2014/34/EU.

Heating/cooling jacket

Temperature-controlled for precise process control with insulating casing.

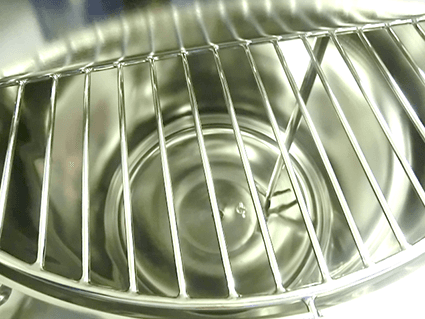

Example: Coating container

Pharmaceutical mixing container for coating liquids

Designation

Pharmaceutical mixing container for coating liquids according to PED 2014/68/EU according to Module G, ATEX RL 2014/34/EU and MRL 2006/42/EU.

Our coating containers are manufactured according to your individual requirements. The following example shows a typical configuration for pharmaceutical production.

Equipment

| Application Area | Industry: Pharmacy Products: Coating liquids, spray liquids |

| Sizes | 10 l – 500 l |

| Operating Data | Product Space: p = -1 / +3 bar, t = -10 / +150 °C Double Jacket: p = -1 / +3,5 bar, t = -10 / +150 °C |

| Material | Product-contacting parts 1.4404 / 1.4435 / 316L, with APZ 3.1 AD 2000, Ra <0.3µm |

IoT capability with IRIS

With our innovative IoT solution IRIS, your coating tank becomes highly efficient through remote monitoring and control. This also works with your existing tanks.

Other container solutions

Discover more container solutions from our portfolio

Do you need a coating container?

Let's discuss your requirements. We'd be happy to advise you and create a customized offer.

We usually respond within 24 hours.