Stirred tank

Perfect mixing for optimal process results

Our stainless steel mixing tanks combine storage and mixing in a single system. With custom-designed agitators for low- to high-viscosity media – for food, pharmaceuticals, chemicals, and cosmetics.

Product features

Tailor-made agitator solutions for a wide variety of mixing and homogenization tasks.

Homogeneous mixing

Optimal mixing quality thanks to precisely matched agitators for a wide range of viscosities.

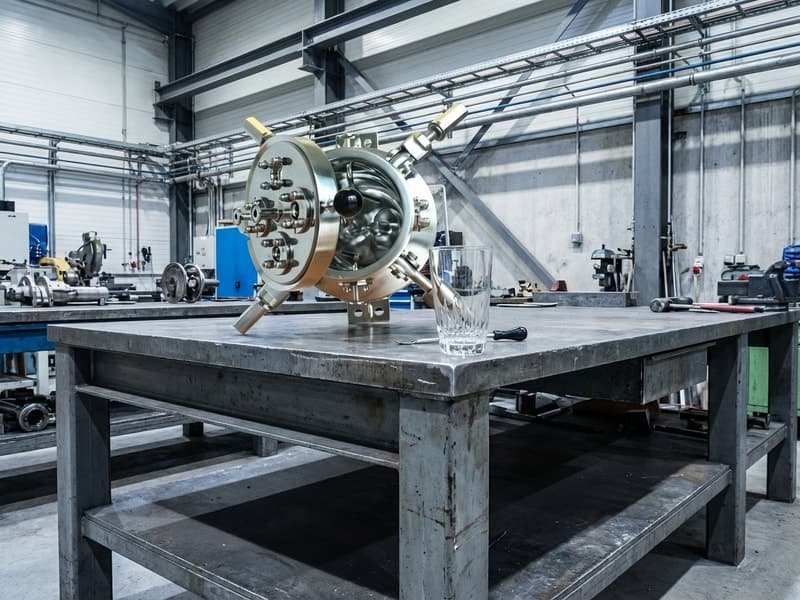

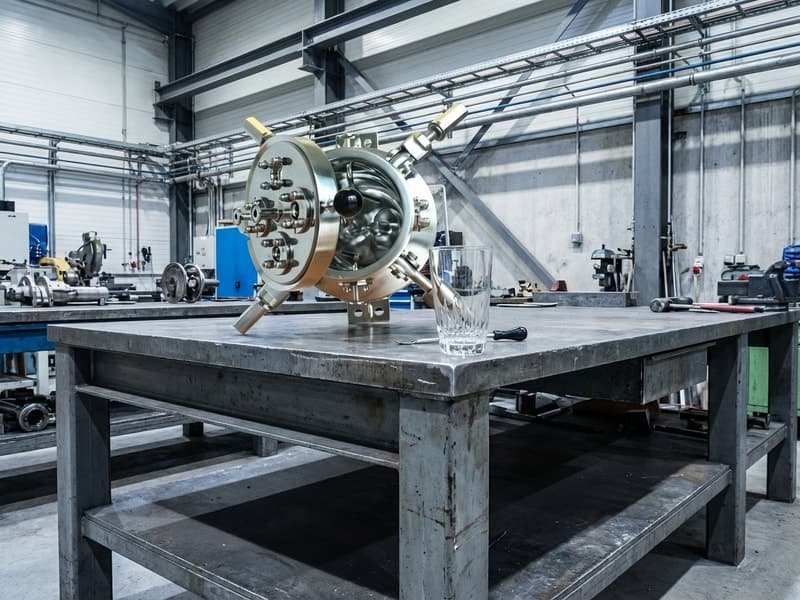

Different stirrer types

Propeller, armature, disc stirrers or magnetic stirrers – individually tailored to your requirements.

Easy cleaning

CIP-compatible design with smooth surfaces for efficient and validated cleaning.

Process reliable

Robust design with precise control for reproducible and reliable mixing processes.

Example: Stirring container for food

Mixing container for liquid foods with temperature control

Designation

Stainless steel mixing tank for mixing and tempering liquid foodstuffs, CIP-compatible design.

Our agitator tanks are manufactured according to your individual requirements. The following example shows a typical configuration for the food industry.

Equipment

| Application Area | Industry: Food, beverages, cosmetics Products: Yogurt, sauces, creams, emulsions |

| Sizes | 50 l – 20,000 l |

| Operating Data | Product Space: p = no pressure / +0.5 bar, t = +5 / +95 °C Double Jacket: p = -0,5 / +3 bar, t = -5 / +100 °C |

| Material | Product-contacting parts 1.4404, outer skin 1.4301, Ra <0.8µm, all product-contacting welds pickled and passivated |

IoT capability with IRIS

With our innovative IoT solution IRIS, your agitator tank becomes highly efficient through remote monitoring and control. This also works with your existing tanks.

Other container solutions

Discover more container solutions from our portfolio

Frequently Asked Questions

Answers to frequently asked questions about our agitator tanks

Do you need a mixing tank?

Let's discuss your requirements. We'd be happy to advise you and create a customized offer.

We usually respond within 24 hours.